Системата Artic Frame

Artic Frame накратко: CNC-обработена рамка Post & Beam, рамка от дървесина по поръчка и повърхностни материали по ваш избор.

Системата Artic Frame е нашият отговор на нуждата от добре изолирани дървени домове. Тази строителна система ни дава възможност да проектираме по-големи отворени планове в сравнение с по-традиционната система Log Home. Вътрешните повърхности могат да бъдат измазани или облицовани с дървени панели - имате пълна свобода на избор на материали при строителство с тази система. Същото важи и за външните повърхности: най-често използваният външен облицовъчен материал е дървена облицовка, но могат да се използват и мазилки или други материали.

Нашите стандартни покрития за стени са гипсокартон или дървени панели отвътре и дървена облицовка отвън. Всички детайли са налични при поискване на подробна оферта.

Екологично и бързо за изграждане

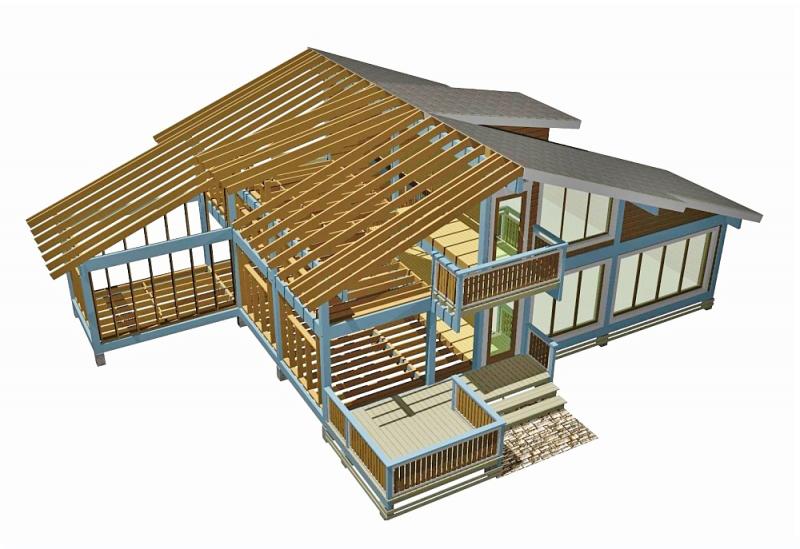

Artic Frame демонстрация

Ламинираните стълбове и греди носят тежестта на къщата, а предварително изрязаните греди и колони допълват конструкциите. Всички прозорци и врати са монтирани в рамката и запечатани с изолационни ленти за осигуряване на въздухонепроницаемост.

Стандартна конструкция

Приблизителните U-стойности при стандартната система Artic Frame са:

Стена: 0,17 W/m²K

Под: 0,13 W/m²K

Покрив: 0,13 W/m²K

Тези стойности са значително под стандартите за Обединеното кралство и могат да бъдат допълнително подобрени за изграждане на още по-енергийно ефективен дом.

Изграждане на къща със система Artic Frame

Това е историята на една от нашите къщи Artic Frame, която се строи в Sutton on the Hill, Derby. Къщата ще бъде шоу дом, като посещения на строителния обект могат да се организират при заявка.

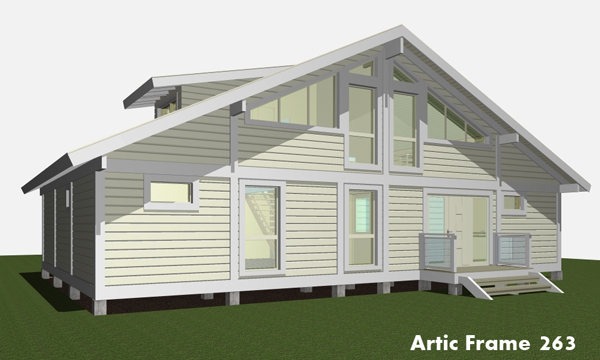

The standard plan has a small enclosed terrace and a balcony on the North elevation.

The small balcony and terrace were removed and replaced with warm area. The customers gained a few extra m2 of living space with a small modification.

Building of the Artichouse kit

Foundation pillars were cast based on Artichouse drawings - showing the exact spot of each pillar. As the production is computerized, all measurements are accurate and the tolerances are minimal.

The buiding kit is being transported to the site, a good 65 cubic metres of goods in the first trailer.

The majority of the building kit is at the site, time to start building the post & beam frame.

Installing the laminated post & beam frame is very fast. All the posts and beams have been precut and machined at the factory to ensure everything goes well at the building site.

After a few hours of hard work, all but the purlin beam is in place!

The floor joists can be installed quickly by using metal fasteners, beam hangers.

The builders started installing the stud structure between the posts and beams.

An exceptionally sunny day at a UK building site. Keeping the packages in order and suspended from the ground makes life easier at the building site. This also ensures the wooden materials stay in good condition as the humidity cannot rise from the ground to the packages.

Purlin beam is in place and the wall studs + roof rafters are being installed. The studs, joists and rafters are vital for the rigidness of the structures.

The first floor is starting to form, one can imagine all the bedrooms and en-suites in place!

A few days later, the roof boarding has been installed. Also all exterior wall studs are in place.

Roof verge boarding is being installed as well as the building board for external walls. The building board is also of vital importance when making the structure rigid.

At this stage you can still see the structures – most of the supporting structures will be hidden beneath the external boarding and paneling when the house is complete.

Breather membrane is being installed on top of the building boards. After this stage the house will be clad with the surface material the customer has chosen.

After the cladding is installed, the house starts to look like a home! The paneling used in this house is a planed spruce cladding from Northern Finland. The cladding has been primed and treated with two layers of translucent treatment at the building site. The treatment will protect the external surfaces for roughly the next seven years. After that a re-treatment is required.

Eaves soffit boarding hides the roof joists and roof boarding from sight. Artic Frame houses can also be delivered with visible roof joists if that is the customer’s choice.

A sunny day and most of the structures are installed. Proper scaffolding is important to ensure the safety of builders.

A rooflight is one of the most cost-efficient ways of gaining more headspace on first floor. The window also brings light to the large bathroom.