The Artic Frame System

Artic Frame in a nutshell: a CNC-machined post & beam frame, made-to-measure timber framing and the surface materials of your choice.

The Artic Frame system is our answer to the need of well-insulated wooden homes. This building system also gives us the opportunity to design larger open plan designs than the more traditional Log Home system. The internal surfaces can be plastered, lined with wooden panels - you have absolute freedom of choice over materials when building with this building system. Also the external surfaces fall under the same rule: the most common external lining material is wooden cladding, but rendered panels or other materials can also be used.

Our standard wall coverings are either plaster board or wooden panels on the inside and wooden cladding on the outside. All details are available when asking for a detailed quotation.

Ecological and fast to build

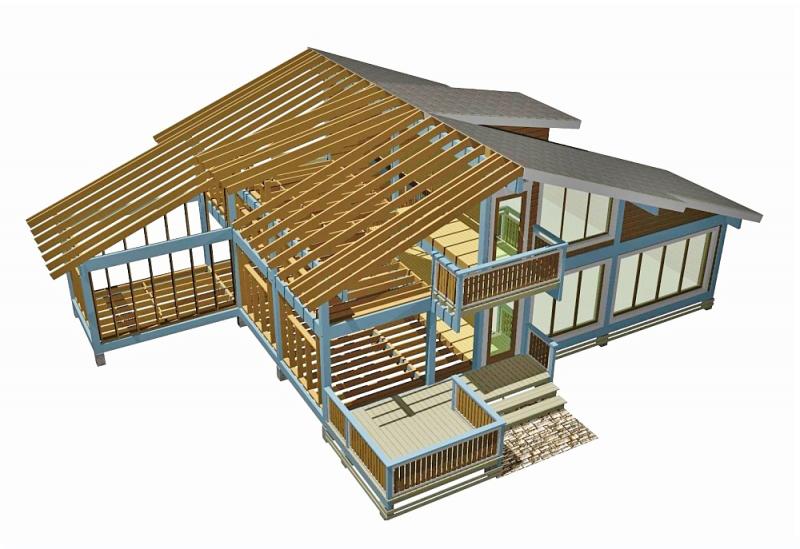

The laminated posts and beams bear the weight of the house and the pre-cut joists and wall studs complement the structures. All windows & doors are installed in the frame and sealed with insulation tapes to ensure airtightness.

Standard construction

You can download a list of the standard contents here.

With our standard Artic Frame construction the approximate U-values are:

- Wall = 0,17 W/m²K

- Suspended floor = 0,13 W/m²K

- Roof = 0,13 W/m²K

These are way below the UK backstop values and can naturally be modified even lower if you want to build a even more low-energy build. Please contact us when you want more information about the Artic Frame system and how much your build would cost with our system.

Building of an Artic Frame house

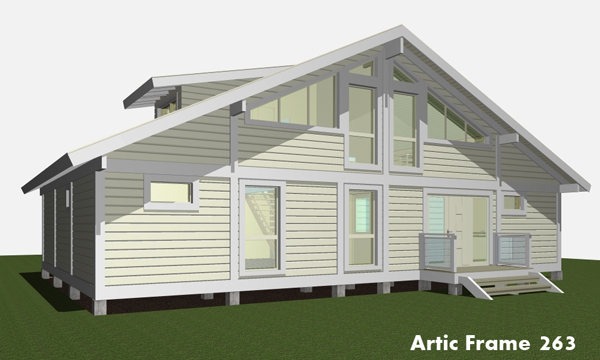

This is a story of one of our Artic Frame houses which is being built to Sutton on the Hill, Derby. The house will be a show home, visits to the building site will be arranged on request. The original design was the Artic Frame 263, to which the customers wanted to make small modifications.

The standard plan has a small enclosed terrace and a balcony on the North elevation.

The small balcony and terrace were removed and replaced with warm area. The customers gained a few extra m2 of living space with a small modification.

Building of the Artichouse kit

Foundation pillars were cast based on Artichouse drawings - showing the exact spot of each pillar. As the production is computerized, all measurements are accurate and the tolerances are minimal.

The buiding kit is being transported to the site, a good 65 cubic metres of goods in the first trailer.

The majority of the building kit is at the site, time to start building the post & beam frame.

Installing the laminated post & beam frame is very fast. All the posts and beams have been precut and machined at the factory to ensure everything goes well at the building site.

After a few hours of hard work, all but the purlin beam is in place!

The floor joists can be installed quickly by using metal fasteners, beam hangers.

The builders started installing the stud structure between the posts and beams.

An exceptionally sunny day at a UK building site. Keeping the packages in order and suspended from the ground makes life easier at the building site. This also ensures the wooden materials stay in good condition as the humidity cannot rise from the ground to the packages.

Purlin beam is in place and the wall studs + roof rafters are being installed. The studs, joists and rafters are vital for the rigidness of the structures.

The first floor is starting to form, one can imagine all the bedrooms and en-suites in place!

A few days later, the roof boarding has been installed. Also all exterior wall studs are in place.

Roof verge boarding is being installed as well as the building board for external walls. The building board is also of vital importance when making the structure rigid.

At this stage you can still see the structures – most of the supporting structures will be hidden beneath the external boarding and paneling when the house is complete.

Breather membrane is being installed on top of the building boards. After this stage the house will be clad with the surface material the customer has chosen.

After the cladding is installed, the house starts to look like a home! The paneling used in this house is a planed spruce cladding from Northern Finland. The cladding has been primed and treated with two layers of translucent treatment at the building site. The treatment will protect the external surfaces for roughly the next seven years. After that a re-treatment is required.

Eaves soffit boarding hides the roof joists and roof boarding from sight. Artic Frame houses can also be delivered with visible roof joists if that is the customer’s choice.

A sunny day and most of the structures are installed. Proper scaffolding is important to ensure the safety of builders.

A rooflight is one of the most cost-efficient ways of gaining more headspace on first floor. The window also brings light to the large bathroom.